Agility Robotics, the brains behind the renowned bipedal robot Digit, is making its name with its new initiative — establishing the world’s first humanoid robot factory to produce 10,000 AI humanoid robots in Salem, Oregon. This 70,000-square-foot facility, aptly named “RoboFab,” is anticipated to start operations later this year, creating a significant advancement in the field of robotics.

About Agility Robotics

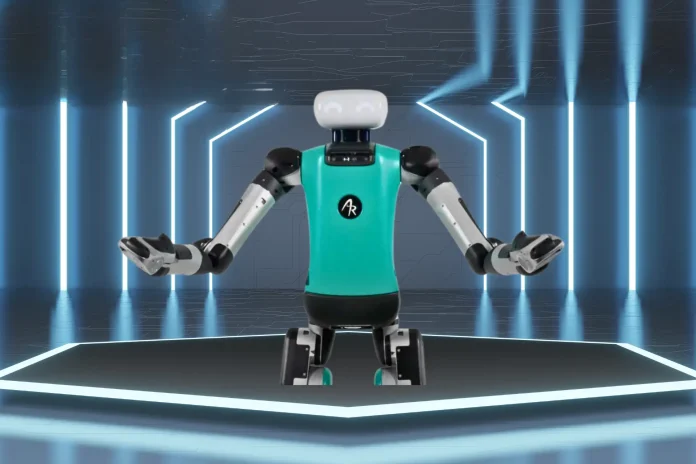

Agility robots are a new generation of robots designed to move and adapt with the skill and grace of humans. Unlike traditional robots, which are often bulky and confined to controlled environments, agility robots are active, lightweight, and able to navigate complex terrain and interact with their surroundings in a more fluid way.

Factory Set to Produce 10,000 AI Humanoid Robots Annually

The primary focus of this state-of-the-art manufacturing warehouse is to produce more than 10,000 humanoid robots annually, showcasing Agility Robotics’ commitment to pushing the boundaries of robot production. “This is a significant moment in the robotics industry,” says Agility Robotics’ co-founder and CEO Damion Shelton.

RoboFab, the Center of Innovation and Production

The ambitious RoboFab is not just a manufacturing factory; it’s an innovation center set to redefine the landscape of robotics manufacturing with enhanced capabilities. The facility is about 30 miles from Agility Robotics’ engineering center, promoting collaboration and efficiency. Shelton emphasizes, “Not only that we’re building it in the United States, but also that we’re so close to the rest of the team.”

Humanoids Assisting in Manufacturing

What sets RoboFab apart is its amalgamation with its Digits — the iconic humanoid robots designed by Agility Robotics. Digits will play an essential role in this manufacturing process, assisting in moving, loading, and unloading warehouse goods. Shelton envisions this as a critical step toward addressing workforce challenges such as injuries, burnout, high turnover, and labor gaps.

Transformative Impact on the Industry

While competitors like Boston Dynamics and Tesla have teased the manufacturing of their robots like BigDog and Optimus, respectively, Agility Robotics takes a step forward by developing humanoids in mass production. The goal is to fill gaps in the logistics and distribution industry. However, the actual impact on the market will only be determined when these robots hit production and fulfil their promises.

In the words of Shelton, “There was a point in time over 100 years ago when we had the world’s first automobile factory. I think this is the same moment we are now having the world’s first humanoid robot factory.” As Agility Robotics embarks on this new journey, the vision is clear — AI humanoid robots, much like automobiles, will soon become popular globally. Agility Robotics is proud to be at the forefront of this revolution.