A unique collaboration has sparked between MIT, Inkbit (an MIT spinout) and ETH Zurich to create a new lead in 3D printing. A novel inkjet MIT 3D printing system utilizing computer vision has been developed, allowing engineers to print with a broader range of materials and enhancing the capabilities of multi-material 3D printing systems.

A Contact-Free Printing Leap

Traditionally, 3D inkjet printing systems utilized thousands of nozzles to deposit tiny droplets of resin, a process that is then smoothed and cured with UV light. However, the smoothing process has its limitations on materials that cure slowly. This latest MIT 3D printing, employing computer vision, transforms the process by automatically scanning the printing surface, adjusting the resin deposition in real time, and eliminating the need for mechanical smoothing.

Vision-Controlled Jetting Technique

The research team introduced a technique called “vision-controlled jetting”, using high frame rate cameras and lasers to scan the print surface continuously. This innovative system can independently adjust the amount of resin deposited by each nozzle, providing remarkable accuracy. Professor Wojciech Matusik from MIT said, “It’s like endowing a printer with a set of eyes and a brain.”

Fast and Adaptable Printing Speed

MIT’s 3D printing system is fast, and a contactless approach sets it apart from all other printers. The automated system adjusts without slowing the printing process, making it approximately 660 times faster than comparable 3D inkjet printing systems. This leap in speed is credited to the real-time adjustment made by the computer vision system.

Expanding the Areas of MIT 3D Printing

The inkjet printer’s ability to work with slower-curing materials, such as thiol-based substances, opens new doors for functionality and durability. These materials offer extended elasticity, stability over temperature variations, and longer life. Dr Robert Katzschmann, leader of the Soft Robotics Laboratory at ETH Zurich, emphasizes, “What you get is truly functional and long-lasting.”

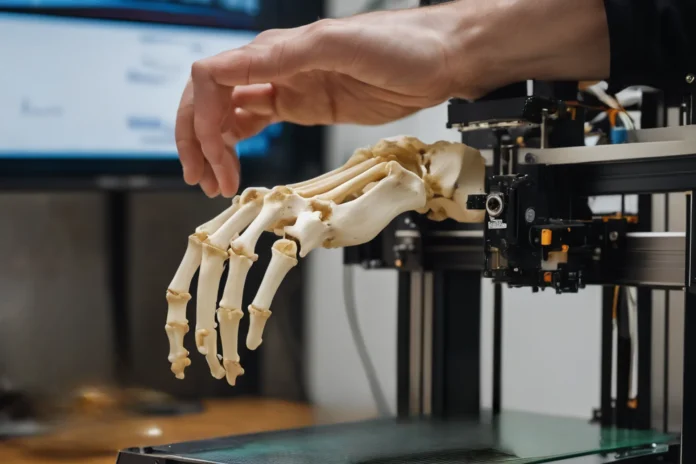

From Robots to Organs

By harnessing the power of MIT 3D printing, MIT researchers showcased the printer’s capabilities by creating intricate robotic devices, including a tendon-driven robotic hand with soft fingers, a six-legged walking robot, and even a heart-like pump with integrated ventricles and artificial heart valves. The system’s creativity extends to fabricating meta-materials with programmable non-linear properties.

The Future of 3D Printing

As the team explores new materials, including hydrogels and durable polymers, the potential applications of this visionary inkjet printer continue to expand. Customizable medical devices, semiconductor polishing pads, and even more complex robots are on the horizon. Professor Matusik envisions, “This is just the start. There is an amazing number of new types of materials you can add to this technology.”

Funded by Credit Suisse, the Swiss National Science Foundation, DARPA, and the NSF, MIT 3D Printing Research Takes a Quantum Leap. This initiative signifies a monumental advancement in the realm of additive manufacturing. By pushing the boundaries of what was once thought unattainable, this research opens doors to new possibilities, revolutionizing the landscape of 3D printing technology.